The Office

↧

↧

Morgan Three Wheeler

↧

Railton Mobil Special

"The Railton Special, later rebuilt as the Railton Mobil Special, is a one-off motor vehicle built for John Cobb's successful attempts at the land speed record.

It was powered by two supercharged Napier Lion VIID (WD) W-12 aircraft engines. These engines were the gift of Marion 'Joe' Carstairs, who had previously used them in her powerboat Estelle V. Multiple engines was not a new technique, having already been used by the triple-engined White Triplex and the Railton Special's contemporary rival, Captain Eyston's twin-engined Thunderbolt. With the huge powers thus available, the limitation was in finding a transmission and tyres that could cope. Reid Railton found a simple and ingenious solution to this by simply splitting the drive from each engine to a separate axle, giving four wheel drive.

On 15 September 1938, the Railton Special took the land speed record from Thunderbolt at 353.30 mph (568.58 km/h), also being the first to break the 350 mph (560 km/h) barrier. Eyston re-took the record within 24 hours (357.50 mph / 575.34 km/h), holding it again until Cobb took it a year later on 23 August 1939 at a speed of 369.70 mph (594.97 km/h).

After the Second World War further development and sponsorship by Mobil Oil led to renaming as the Railton Mobil Special. It was the first ground vehicle to break 400 mph (640 km/h) in a measured test. On September 16, 1947 John Cobb averaged 394.19 mph (634.39 km/h) (385.6 & 403.1) over the measured mile in both directions to take the world land speed record.

It weighed over 3 tonnes and was 28 ft 8 in (8.74 m) long, 8 ft (2.4 m) wide and 4 ft 3 in (1.30 m) high. The front wheels were 5 ft 6 in (1.68 m) apart and the rear 3 ft 6 in (1.07 m). The National Physical Laboratory's wind tunnel was used for testing models of the body.It was designed by Reid Railton and is currently on display at the Thinktank museum in Birmingham, England."

↧

Corner action

↧

1978 Ducati Desmo 900 Super Sport road test

↧

↧

Chevrolet Corvette GSII 1963

After the American Manufacturer's Association (AMA) ban on direct factory involvement in competition, companies like Chevrolet were limited to research and design vehicles that assisted private teams. This kind of relationship was formed between Chevrolet and Chaparral and that's precisely where the GS-II fits in.

Despite being labeled as a Corvette by GM marketing, the GS-II was an experimental race car that paralleled Chaparral development. The project was headed by F.J. Winchell, vice-president of GM engineering, who wanted to build a mid-engine Sportscar that would out perform and become an extension of the Grand Sport (GS-I) Corvettes. He probably named it Corvette to avoid Chevrolet bureaucracy while at the same time using it to test highly advanced racecar engineering.

The design was loosely based around the Monza GT concept car which used Corvair running gear in Chevrolet's first monocoque design. But unlike the Monza GT, the GS-II took the theme several steps further by using light-gauge steel, an experimental 327 V8 engine that was all-aluminum and a one-speed transmission.

Having Chevrolet research and design at his fingertips, Jim Hall at Chaparral embraced many of the new technologies from Chevrolet and the GS-II. This meant both companies had a symbiotic relationship that was hard to manage since Chevrolet was not supposed to be directly involved in the first place. The fact that the Chaparral 2C had a remarkable resemblance to the GS-II was no coincidence.

The GS-II was initially built around a steel monocoque chassis and an extremely thin fibreglass body designed by Larry Shinoda. The chassis was later replaced by a very lightweight aluminum counterpart and became known as the GS-IIb. Chaparral modified the aluminum tub design for his 2C which many drivers didn't trust due to its extremely low weight. However, it retained so much rigidity that Jim Hall nicknamed it the 'eyeball jiggler'.

The one-speed automatic transmission was developed by engineer Jerry Mrlik at Chevrolet to help deliver monstrous power to tires that could barely cope. It used a torque converter and a single-speed transaxle to send varying amounts of power the rear wheels. The same unit was also used in the Chaparral 2C which won to everyone's surprise the first few times out! These automatics, in both one and two speed configuration, were very reliable and helped Chaparral win 16 major American road races in 1965.

To test various wheel/tire combinations, the wheels were also special on the GS-II . Chevrolet devised a multi-piece design that could be more easily changed without having to mount cumbersome race tires. The solid disc design overheated the brakes in testing and were adopted by Chaparral for a very limited time.

Suspension for the GS-II came from another car called the Suspension Test Vehicle (STV). This crude test mule lent its developments including a fully independent front and rear setup.

The results achieved with the GS-II were phenomenal. Engineer Jim Musser did a test run at the proving grounds that reached 198 mph. This was in large part due to the cars low weight. At just 1450 lbs, the large block V8 had no problem propelling the GS-II.

Sitting somewhere between a sports car and a race car, the GS-II never left its experimental role. It was followed up by the GS-III an experimental open-wheeled car that was a possible Indianapolis contender. Beyond the GS-II, several more mid-engine Corvette prototypes were made, but none were suitable enough for production, nor as radical as the GS-II.

↧

7

↧

Frank Lockhart's Stutz Black Hawk Special

"Perhaps the only thing faster than Frank Lockhart’s phenomenal rise on the early auto racing scene, was the tragic end of his career. Nicknamed “Boy Wonder” by the press, Lockhart only raced at the Indianapolis 500 twice. His first run was in 1926 when he took the place of an injured driver in a 183 cu in (3.0 L) Miller race car. During practice, he set a one-lap track record of 115.488 mph (185.86 km/h). During the race, he passed 14 cars on the fifth lap as he made his way to the front from starting 20th. He went on to win the race with over a two lap lead.

At Indianapolis in 1927, Lockhart qualified first, at 120.100 mph (193.28 km/h). At the time, it was the fastest lap ever recorded on the track. He led the first 81 laps of the race, a record that would stand for 64 years. After a pit stop, he regained the lead on lap 91, only to have a connecting rod break on lap 120 and take him out of the race. Of the 280 laps he ran at Indy, he led 205 (73.21%) of them. Lockhart is one of only three drivers to have led more than 45% of their laps at Indy, and he has the second highest percentage overall (Juan Pablo Montoya has the highest percentage of laps led at 83.50%, for 167 laps led of 200 run).

In May of 1927, Lockhart set a qualifying record of 147.729 mph (237.74 km/h) on the 1.5-mile (2.4 km) board track at Atlantic City, New Jersey in his 91 cu in (1.5 L) Miller race car. It wasn’t until 1960, 33 years later, that another driver turned a faster lap at an American speedway. In his short American Automobile Association (AAA) career, Lockhart started 61 races, won 27 of them and finished in the top three 37 times.

But Lockhart was more than just a race car driver; he was an innovator with the mind of an experimental engineer. Between the 1926 and 1927 season, Lockhart and his team, which included Zenas and John Weisel and Ernie Olsen, developed an intercooler for Lockhart’s supercharged 91 cu in (1.5 L) Miller engine. They had noticed that while the supercharger pressurized the air, it also heated it, making it less dense. If the air could be cooled, the denser air would allow the engine to create more power. Later in the year on 13 June 1927, Lockhart filed a patent for his intercooler, and U.S. patent no. 1,807,042 was issued on 26 May 1931.

On 11 April 1927, Lockhart took his standard Miller race car to the Muroc Dry Lake in California for an International Class F record attempt. This race car was powered by a supercharged Miller 91 cu in (1.5 L) engine equipped with Lockhart’s intercooler. Lockhart established a new class record, averaging 164.009 mph (263.947 km/h). At that speed, Lockhart became the fourth fastest driver ever, behind only Henry Seagrave’s 203.793 mph (327.973 km/h) run in the Sunbeam 1000 HP Mystery (The Slug), Malcolm Campbell’s 174.883 mph (281.447) run in the Napier-Campbell Blue Bird, and J.G. Parry-Thomas’s 171.019 mph (275.229 km/h) run in Babs. All of the faster vehicles were purpose-built Land Speed Record (LSR) cars powered by large, powerful aircraft engines.

By mid-1927, Lockhart had become focused on building a LSR car to break Seagrave’s current world speed record of 203.793 mph (327.973 km/h). Lockhart partnered with Fred Moskovics, President of the Stutz Motor Car Company, to build the special LSR car. Lockhart and the Weisel brothers designed the LSR car. The Stutz Company funded about half of the project, so the LSR car would wear the Stutz name. Lockhart funded the rest of the project from his race winnings.

A team was assembled in Indianapolis to build the LSR car. What emerged on 12 February 1928 was the Stutz Black Hawk Special—a comparatively small streamlined car powered by a 180.4 cu in (2.96 L) Miller V-16 (more accurately a U-16) engine with intercooled twin superchargers. The intercooler was formed into the engine cover, allowing air flowing over the car’s body to cool the air/fuel mixture before it entered the engine. The car was made up of a central body, with each wheel housed in its own streamlined fairing. The Black Hawk was perhaps the first car to be designed with the aid of a wind tunnel. Scale models were tested in both the Curtiss and the Army Air Services wind tunnels. The car’s wind resistance was measured as .0061 lb/mph². The Black Hawk was 15 ft 9 in (4.80 m) long with a 112 in (9.33 m) wheelbase. The body was only 24 in (0.61 m) wide, and the car’s total width including the wheels was around 60 in (1.52 m).

The engine was basically two 91 cu in (1.5 L) Miller inline-eight engines installed 30-degrees apart on a common crankcase. Each straight-eight engine’s crankshaft was geared to a central gear at the rear of the engine. The flywheel was attached to the central gear. To cool the engine, a tank in the font of the car held a radiator that was cooled with 80 lb (36 kg) of ice. The engine’s bore was 2.1875 in (55.56 mm), stroke was 3.0 in (76.2 mm), and weight was around 630 lb (286 kg). The engine produced more than 550 hp (410 kW) at 8,300 rpm and, utilizing the wind tunnel data, was predicted to propel the 2,800 lb (1,270 kg) Black Hawk LSR car to a maximum speed over 280 mph (450 km/h). The estimated cost of the LSR car was between $70,000 and $100,000 ($0.9 to $1.3 million in 2013 USD).

Lockhart joined Campbell and other racers at Daytona Beach, Florida in mid-February 1928 for speed record runs sanctioned by the AAA. On 19 February, Campbell set a new record at 206.956 mph (333.064 km/h) in the now more-streamlined Napier-Campbell Blue Bird. The next day, Lockhart made one run against the wind at 200.222 mph (322.226 km/h). This was slightly faster than Campbell’s against the wind run from the previous day. Unfortunately, clutch issues prevented Lockhart from making the return run.

With the sanctioned event coming to a close, Lockhart made another run on 22 February in bad weather conditions. During the run at over 200 mph (322 km/h), Lockhart encountered a rain-squall that reduced his visibility to nothing. He lost control of the car, and the Black Hawk spun into the sea, rolling over several times. Lockhart was pinned in the car as the waves crashed over his head. Spectators rushed to his aid, shielding him from the incoming waves and holding his head above the water while others attached ropes to the car. More spectators joined in and began dragging the car to the beach, until a tow truck arrived to pull it the rest of the way in. Lockhart had to be freed from the wreck with the aid of crowbars and blowtorches. He suffered three severed tendons in his left wrist, some bad bruising, and was in shock.

The Black Hawk was transported back to Indianapolis where it was quickly rebuilt and repaired. Lockhart, his car, and his team arrived back at Dayton Beach on 20 April 1928, only two months after his accident. Again, the speed record runs were sanctioned by the AAA, and other racers were present. Also making runs was Ray Keech in the White Triplex, a vehicle powered by three Liberty V-12 aircraft engines.

On 20 April 1928, Lockhart made a run and achieved 200.33 mph (322.40 km/h) on the return leg. The Black Hawk’s Miller engine was suffering carburation problems. Meanwhile, Keech made a series of runs, steadily improving in speed. On 22 April 1928, Keech got the Triplex up to an average of 207.55 mph (334.02 km/h), setting a new world record.

On 25 April 1928, Lockhart made a test run during which his rear right tire locked up under breaking during the return. The carburation problems seemed to be resolved, and by 7:30 AM, Lockhart was making another run. The first leg was recorded at 203.50 mph (327.50 km/h), and everything went well. As the Black Hawk was prepared for the return run, Lockhart told his team that he was going to go for the record. Screaming down the beach at over 220 mph (355 km/h), about 700 ft (213 m) before the end of the course, the right rear tire blew, and the Black Hawk went out of control. The car skidded in the sand for about 400 feet (122 m), went sideways, and became airborne. The Black Hawk traveled another 503 ft (153 m), crashing down on the beach several times as it rolled. Lockhart was thrown 51 ft (15 m) from the vehicle. He was transported to a hospital where he was pronounced dead, Lockhart was only 25 years old.

Subsequent investigation revealed that the right rear tire had been damaged at some point during earlier runs. The tire had continued to deteriorate as the additional passes were made. The 16-cylinder engine was salvaged from the Black Hawk wreck. It was rebuilt and installed in the Sampson “16″ Special, owned by Alden Sampson. Bob Swanson raced the car in the 1939 and 1940 Indy 500, finishing sixth in 1940. The car was also driven by Deacon Litz in 1941 and Sam Hanks in 1946. The Sampson “16″ Special, with the 16-cylinder engine still installed, is currently on display at the Indianapolis Motor Speedway Hall of Fame Museum in Indianapolis, Indiana.

There are two Lockhart Stutz Black Hawk replicas. One replica is owned and displayed by Turner Woodward in his historic Stutz Building in Indianapolis, Indiana. The second is a running (but not with a 16-cylinder engine) replica that is being finished by Jeb Scolman of Jebs Metal and Speed in Long Beach, California."

↧

The waiting is the hardest part

↧

↧

Martin B57

"The design of the B-57B definitive production version of the US-built Canberra began in early 1952, when the Air Materiel Command and the Air Research and Development Command recognized the basic deficiencies in the B-57A configuration. In March, they presented a list of the problems and shortcomings that had been encountered with the Canberra to Air Force Headquarters. In April, the two Commands provided the Air Council with a list of minimum changes that would be needed to make the B-57A into a useful combat aircraft. The Air Force committed the new aircraft to production on August 11, 1952. The aircraft was assigned the designation B-57B.

Letter Contract AF 32(038)-22617 of March 1951 had originally called for the production of 250 B-57s, but it was amended several times. In the agreement of August 11, 102 B-57Bs were substituted for 70 B-57As and for 32 RB-57As. In Letter Contract AF 33(600)-22208, which was issued on September 19, 1952, 119 more B-57Bs were added. It was amended on December 18, bringing the Fiscal Year 1953 B-57B procurement to 191, and bringing the planned total production of the B-57B to 293.

However, the production order was not to remain at that level. In early 1954, the USAF cut back the FY 1953 B-57B procurement to 158 (a 33-aircraft reduction) and dropped the tentative order for 50 more. In the spring, 38 additional B-57Bs were cut in favor of an equal number of B-57C dual-control trainers. A few months later, 20 additional B-57Bs were diverted to the B-57D program, bringing the total reduction to 91 aircraft In the event, a total of 202 B-57Bs were built, more than all the other versions put together.

The most significant change introduced by the B-57B was the complete redesign of the cockpit area. The navigator/bombardier was moved from the "buried" position in the fuselage behind the pilot and moved upwards to a position behind the pilot, with both crew members seated in tandem underneath a large clamshell-opening bubble canopy. This arrangement improved visibility, provided more space for equipment, and made it easier for the navigator/bombardier to escape from the aircraft in the event of an emergency. The new arrangement also made for better communication between the two crew members. Although the pilot's seat was on the aircraft centerline, the navigator's seat was lightly offset to left of center to provide room for a Shoran receiver-indicator and the M-1 toss-bomb computer unit. The B-57B also introduced a flatplate windshield which permitted the installation of a gunsight, which was impossible in the B-57A because of the distortion and flexing of the latter's curved one-piece canopy. The tandem cockpit seating arrangement was first tried out on Canberra WD940, but it is not certain if the aircraft was ever actually flown in this configuration. The first true B-57B flew on June 18, 1954.

Four external pylons were fitted underneath each wing that could carry bombs or rockets. A 17-foot long, one-piece rotating bomb door was incorporated, which was a feature originally developed for the XB-51. The door rotated 180 degrees around two pivots, taking four seconds to open and six to close. The bombs were attached directly to the inward side of the door, so that when the door was rotated open the bombs were in an externally-mounted position. The attachment points on the door allowed a wide variety of stores to be carried, including nuclear weapons. The rotating door also made it possible to make bombing runs at higher speeds because the buffeting associated with conventional bomb doors when they were opened was eliminated. The development of this door was the main reason why the B-57 became the most accurate of the aircraft using the LABS. Another advantageous feature was that the entire door could easily be removed from the aircraft while it was on the ground, making it possible to pre-load the door with ordnance and quickly winch it into place inside the fuselage, enabling a rapid turnaround.

An APW-11 Bombing Air Radar Guidance System was provided, helping the pilot to make accurate runs into the target. The Shoran bombing system was added for use by the bombardier/navigator. An APS-54 Radar Warning System was provided, which increased the angle of coverage astern of the aircraft and gave the crew some warning of AI illumination.

There were important changes to the starter system, with the manually-operated cartridge of the RB-57A being replaced by one that was electrically-ignited. A pyrotechnic cartridge was loaded into a breech in the center of the engine air intake. When ignited, the cartridge drove a starter turbine which brought the engine up to a self-sustaining rpm via a clutch system. This eliminated the need for heavy and bulky ground starting units, but the starter cartridge spewed out a characteristic dense cloud of choking black smoke, which was often mistaken by inexperienced ground crews for an engine fire.

The new B-model had a set of speed brakes installed at the waist position of the fuselage. It was found that the finger-like spoilers on the top and bottom of the outer wing panels did not provide sufficient drag for speed control, and these were supplemented by the waist speed brakes. It would turn out that the speed brakes would be very useful in controlling acceleration during diving passes in the ground attack role.

Some other features incorporated on the B-57B worth mentioning are wing surface and engine inlet anti-icing, anti-skid wheel brakes, a drag chute for landing on short runways, and power boost controls.

A forward-firing armament was fitted to the B-57B. The B-57B initially mounted eight 0.5-inch machine guns, four in each wing in pairs outboard of the engine nacelles. Each wing carried 300 rounds of ammunition. After the 83rd B-57B (52-1575), the eight 0.50-inch forward-firing machine guns in the wings were replaced by four M-39 20-mm cannon, two in each wing. The cannon were fixed to fire downwards at 3.5 degrees from the flight path. Each gun had 290 rounds of ammunition. The mounting of cannon in place of machine guns involved airframe alteration and considerable wing modifications. Consequently, machine-gun equipped B-57Bs were not converted to the cannon weapons.

According to the original licensing agreement with English Electric, the name Canberra was also to be used to describe the Martin-built version of the British-designed twin-jet bomber, both by the Glenn L. Martin Company itself and also by the US Air Force. Although the official popular name of the B-57 was indeed listed as Canberra by the Air Force, this name was not used very often in practice, the aircraft being referred to simply as B-57.

The first few B-57Bs to be built had a natural metal finish, but the remainer were finished in gloss black overall, in fitting with their night intruder role.

The first true B-57B flew on June 18, 1954. The first organization to re-equip with the B-57 was the 345th Bomb Group (Tactical), based at Langley AFB in Virginia. The 345th was initially responsible for training its own crews. However, in the spring of 1955 a special B-57 operational conversion unit was formed--the 3510th Combat Crew Training Wing (CCTW) at Randolph AFB in Texas. Shortly thereafter, a second B-57B unit, the 461st Bomb Group (Tactical) was formed at Hill AFB in Utah, receiving its first B-57Bs in January of 1955. In the summer of 1955, they moved to Blytheville AFB in Arkansas. The 461st BG was, in fact, the first of the Bomb Groups to be fully equipped with B-57s.

B-57B units were also formed overseas. In 1956, the 38th Bomb Group (Tactical) was formed at Laon AB in France. The 3rd Bomb Group in the Far East at Johnson AB in Japan traded in its B-26s for B-57Bs in 1957.

From the beginning, emphasis was placed on rapid deployment of the B-57B overseas in the event of a crisis. Tactical cooperation procedures were worked out in late 1956 in Exercise Sagebrush, which involved joint operations by the 461st BG and the RB-57As of the 363rd TRW and was carried out across the southeastern portion of the USA. The 461st TBG and the 363rd TRW were the aggresors in the exercise. In 1957, 13 B-57s of the 461st BG embarked on a goodwill tour of Latin America, after which it deployed to Laon in France to fly alongside the 38th BG in Exercise Counter Punch, NATO's annual tactical air exercise.

Like the RB-57As, the B-57Bs suffered from engine malfunctions which filled up the cockpit with toxic fumes, which led to a brief grounding. The culprit turned out to be the engine compressor, which was quickly fixed and the grounding order was lifted. Difficulties with the aircraft's stabilizer control system led to another grounding order in February of 1955. The B-57Bs were released for flight a month later, but were restricted to a maximum speed of only 250 knots pending the modification of the horizontal stabilizer and the installation of a different stabilizer trim switch.

During this period a number of B-57Bs were lost in accidents, particularly during high-speed, low-level operations when aircraft suddenly and unexplainedly dove into the ground. As these accidents persisted, all tactically-assigned B-57Bs were grounded again in May of 1956 for a period of four months while the problem was investigated. The fault was eventually traced to a faulty tailplane actuator which set the trim incorrectly. The installation of a new actuator switch cured the problem.

The USAF was not very happy with the B-57B as it was initially produced. It was still deemed to be inadequate to meet the night intruder and close support role for which it had originally been designed. The target acquisition system was inadequate, the navigational range was too short, and the radio navigation could not recover the aircraft after strikes. The armament was inadequate--the gun-bomb-rocket sight, the gun charging systems, and the external stores release mechanisms were all unreliable. In September 1955, the Air Force organized a three-phase program to bring the B-57B up to tactical standards. Phase 1 installed the low altitude bombing system (LABS), the AN/APS-54 Search Radar, and the ALE-2 chaff dispenser. Phase 2 added the M-1 toss bomb computer and the AN/APG-31 tie-in equipment. This phase also involved modifications to the longitudinal control and stabilizer systems and to the fuel control panels and special weapon bomb bay doors. Phase III dealt with the AN/APN-59 radar beacon, which was destined never to be installed. These modifications were carried out by Martin subcontractors in the USA and overseas. These modifications were still in progress in late 1957.

The service life of the B-57B with USAF tactical bomb groups was destined to be brief. After three years of service with the B-57s in tactical bomb groups, the decision was made to phase out the B-57 in favor of supersonic aircraft. By the end of 1957, the tactical squadrons of USAFE had began to re-equip with the F-100 Super Sabre, and early in 1958, the 38th BG returned to the USA to begin deactivation. In April of 1958 the 461st BG began to deactivate at Blytheville AFB. As the active duty USAF TAC bomb groups deactivated, their aircraft were transferred to the Air National Guard (ANG)

The 345th BG was about to deactivate at Langley AFB when one of its squadrons had to be hastily deployed in July of 1958 to Incirlik Air Base in Turkey to make a show of force in response to a crisis in Lebanon. They stayed there three months. After the Lebanon crisis was defused, the B-57Bs were returned to Langley AFB.

The deactivation of the 345th BG was further delayed by a crisis in the Taiwan Straits. In August of 1958, Mainland Chinese forces began bombarding the Nationalist-held island of Quemoy. In late August, the 345th BG sent a detachment of B-57Bs to Okinawa to stay on alert just in case mainland forces tried to invade Taiwan. The 3rd BG stood by in Japan to strike strategic targets in China, North Korea and possibly even the Soviet Union should the crisis escalate out of control. Fortunately, the crisis soon cooled and hostilities were averted, and the 345th BG returned to the USA to begin deactivation. This was completed in June of 1959.

This left the 3rd Bombardment Group based in Japan as the sole active B-57 USAF unit. Since nuclear weapons could not be stationed in Japan, in August of 1958, the 3rd BG set up a rotation of crews to stand nuclear alert at Kunsan (K-8) air base in Korea. This rotation continued until April of 1964, when the 3rd BG returned to Yokota to begin the process of inactivation.

This would ordinarily have been the end of the service of the B-57B with the USAF, with the 3rd BG being inactivated and all its planes being transferred to the Air National Guard. However, the worsening situation in Indochina led to orders for the 8th and 13th Bomb Squadrons of the 3rd BG to deploy to Clark AFB in the Philippines for possible action in Vietnam. As it happened, this move did not take place until August 5, following the Gulf of Tonkin incident in which North Vietnamese gunboats clashed with US destroyers.

According to the initial plan, 20 B-57Bs of the 8th and 13th BS were to be deployed to the Bien Hoa air base near Saigon. This would mark the first deployment of jet combat aircraft to Vietnam. This was technically a violation of the Geneva Protocols which forbade the introduction of jet combat aircraft to Vietnam, but the Gulf of Tonkin resolution which had just been passed by Congress was taken as a pretext to remove all such restrictions.

The initial deployment to Vietnam got off on the wrong foot. The first two B-57Bs to land collided with each other on the ground and blocked the runway at Bien Hoa, forcing the rest of the flight to divert to Tan Son Nhut Airport on the other side of Saigon. One of the B-57Bs dived into the ground during approach at Tan Son Nhut and was destroyed, killing both crew members.

During the next few weeks, more B-57Bs were moved from Clark AFB to Bien Hoa to make good these losses and to reinforce the original deployment. Things got so crowded at Bien Hoa at that time that some of the B-57s had to be sent back to Clark AFB. Initially, the B-57Bs were not cleared for actual combat missions, the aircraft being restricted to unarmed reconnaissance missions that were mainly designed to boost the morale of the population.

However, actual combat was not to be delayed very long. On November 1, 1964, Viet Cong squads shelled the airfield at Bien Hoa with mortars, destroying five of the B-57s parked there and damaging 15 others. Further Viet Cong mortar attacks led General William Westmoreland on February 19, 1965 to release B-57Bs for combat operations. The first such mission took place on that same day, a strike against suspected Viet Cong guerillas near Bien Gia, about 30 miles east of Saigon. This strike was, incidentally, the first time that live ordnance had been delivered against an enemy from a USAF jet bomber.

The B-57Bs hit North Vietnamese territory for the first time on March 2, some 25 miles north of the DMZ. This was the first of a series of interdiction strikes that came to be known as *Rolling Thunder*. The usual bomb load on these operations was nine 500-lb bombs carried in the main weapons bay and four 750-lb bombs on the underwing pylons.

In April of 1965, B-57B crews began night interdiction strikes against enemy supply lines along the Ho Chi Min Trail. Operations were carred out in cooperation with C-130 or C-123 flare-deploying aircraft that illuminated potential targets and with USMC EF-10B Skyknight electronics warfare aircraft that jammed radar-controlled AAA and detected enemy missile sites that were preparing to launch.. Eventually these night interdiction missions extended into North Vietnam, the first such attack taking place on April 21, 1965. However, it was considered too dangerous to fly C-130 flare-deploying aircraft into North Vietnamese airspace, so each B-57B carried a set of MK-24 flares in addition to bombs.

On May 16, 1965, while waiting to takeoff on a mission, a B-57B exploded on the ground at Bien Hoa, setting off a whole chain of secondary explosions. The resulting conflagration destroyed ten B-57s, eleven VNAF A-1H Skyradiers, and a US Navy F-8 Crusader. The surviving B-57s were transferred to Tan Son Nhut and continued to fly sorties on a reduced scale until the losses could be made good. Some B-57Bs had to be transferred to Vietnam from the Air National Guard, and 12 B-57Es had to be withdrawn from target-towing duties and reconfigured as bombers to make good these losses.

In June of 1965, the 3rd Bomb Group moved to Da Nang to carry out night interdiction operations over North Vietnam and Laos. Principal targets were trucks, storage and bivouac areas, bridges, buildings, and AAA sites. When deployed at Da Nang, the 8th and 13th Squadrons came under operational control of the 6252nd Tactical Fighter Wing which became the 35th TFW about a year later.

Combat attrition in the B-57 force plus the increasing availability of higher performance fighters to carry out the air war against the North caused the 3rd BG to be withdrawn from operations against the North in October of 1966 and relocated to Phan Rang, just south of Nha Trang and Cam Ranh Bay. It carried out attacks against Communist forces in the Central Highlands and supported US ground troops in the so-called "Iron Triangle". While there, the B-57s operated alongside the Canberra B.20s of No 2 Squadron of the Royal Australian Air Force.

In January of 1968, the 13th Bomb Squadron was deactivated, and the 8th BS was left in permanent residence at Phan Rang. The main emphasis was again on night interdictions against the Ho Chi Minh Trail. By July of 1969, the 8th BS's strength was down to only 9 aircraft, and it was decided that it was time to retire the B-57B from active service. The surviving aircraft were sent back to the USA in September and October and put into storage at Davis Monthan AFB. The identity of the 8th BS was transferred to another unit at Bien Hoa to become the 8th Attack Squadron, which was equipped with Cessna A-37s.

Out of the 94 B-57s that were assigned to the Southeast Asia theatre, 51 were lost in combat (including 15 destroyed on the ground). 11 were withdrawn early to support the B-57G program."

↧

Aermacchi

"The bikes produced by Aermacchi were quite successful in the postwar Italian market, also thanks to their repeated placements on the race tracks. The firm designed and produced models incorporating the Italian word "Ala" (wing) in its names, such as "Ala Verde", "Ala Blu" and "Ala d'Oro" (respectively "green wing", "blue wing" and "golden wing")."

↧

Rockstars' Garage: Ringo Starr's Facel Vega

"The Facel Vega was a fast, stylish exercise in French elegance that was produced from 1954 to 64. Powered by mighty Chrysler hemi V-8s, Facel Vegas wrapped gorgeous coachwork around dependable luxurious interiors that put them in a class by themselves.

Celebrity owners flocked to Facel Vegas, including Frank Sinatra, Ringo Starr, Princess Grace (Kelly), Joan Collins, Christian Dior, Stanley Donen, Tony Curtis, Danny Kaye, Ava Garnder (owned 3), and Joan Fontaine. Writer Albert Camus died at 46 when a Facel-Vega driven by his publisher hit a tree in the south of France.

There was little competition for a four seat luxury tourer like the Facel Vega in its day and only a Ferrari was faster. The glamorous Italian-American Dual-Ghia was probably the closest equivalent but it lacked the performance of the Facel Vega. Their approaches were the same and yet opposite. The Dual-Ghia was made by shipping Italian bodies to the U.S. where their American drivetrains were installed. The Facel Vega shipped American drivetrains across the Atlantic for installation in French bodies.

The Facel II, seen above was introduced in 1962 and built until the company failed in 1964 due to a troubled attempt to build a less expensive, mass produced model with an innovative new engine."

(Via:http://www.examiner.com)

↧

Kenny at Imatra

↧

↧

Cecil Crawford's chain broke and Brian Steenson towed him back to the pits

↧

Brough Superior SS100

"The Brough Superior SS 100 was designed and built by George Brough in Nottingham, England in 1924.Although every bike was designed to meet specific customer requirements—even the handlebars were individually shaped—sixty-nine SS100s were produced in 1925 and at £170 were advertised by Brough as the "Rolls Royce of Motorcycles". The term was coined by magazine road tester in his review of the bike, and Brough eventually obtained explicit permission to use it after a Rolls-Royce executive toured the Brough Superior factory. All bikes had a guarantee that they were capable of 100 mph (160 km/h). The SS100 (Super Sports) was the first custom motorcycle with components chosen from many different suppliers. The first engine (from 1924 to 1936) was the twin-cam KTOR JAP (made by J. A. Prestwich) V twin (upgraded to a Matchless engine from 1936. Gearboxes were the 4-stud 3-speed from Sturmey-Archer. Brough developed the features of the Harley-Davidson forks and produced his own version (made by the Castle Fork and Accessory Company) to combine light weight with strength that was to become a feature of the SS100 handling.

After the initial introduction of the SS100, the Alpine Grand Sport, an SS100 with a full touring specification. was launched at the 1925 Motorcycle Show. In the same year Brough Superior produced a 110 mph (180 km/h) Pendine Racing Model (named after the Pendine Sands where Malcolm Campbell set a number of world speed records) with increased ground clearance.

Every owner was encouraged by Brough to suggest their own ideas for developing the SS100, which meant that almost all his motorcycles were uniquely hand-built and the design continually evolving. The Sturmey-Archer gearbox was upgraded in 1929 for a three speed "super heavyweight" box to cope better with the 50 bhp (37 kW) produced by the JAP engine. In 1928 Brough introduced rear suspension and in 1934 the Alpine Grand Sport gained a 75 hp (56 kW) overhead valve JAP engine known as two of everything as it had two magnetos and two oil pumps. A foot gear-change was introduced in 1935 and a four-speed Norton gearbox in 1936. Development on all Brough Superiors was stopped during the Second World War, when the factory had to be turned over to war work.

The SS100 engineering was developed through competition and wins in over 50 events in the early 1920s, and H. Le Vack, who worked with Brough on development, was the holder of seven world records. In 1927 George Brough and Freddie Dixon both achieved a record 130 mph (210 km/h) for the kilometre on the SS100 and in 1928 Brough broke his own record with 130.6 mph (210.2 km/h). In 1932 Ronald Storey achieved 81,08 for the standing half-mile at Brighton and in 1939 Noel Pope secured an all time Brooklands track record lap time of 124.51 mph (200.38 km/h) on an SS100.

T. E. Lawrence (known as Lawrence of Arabia) bought one of the first SS100s in 1925 having previously owned three Brough SS80’s. The crash that would end Lawrence's life came while riding another SS100, on a narrow road near his cottage near Wareham in 1935. The accident occurred because a dip in the road obstructed his view of two boys on bicycles. Swerving to avoid them, Lawrence lost control and was thrown over the handlebars. He was not wearing a helmet and suffered serious head injuries that left him in a coma; he died after six days in hospital. One of the doctors attending him was the neurosurgeon, Hugh Cairns. He consequently began a long study of what he saw as the unnecessary loss of life by motorcycle dispatch riders through head injuries and his research led to the use of crash helmets by both military and civilian motorcyclists. As a consequence of treating Lawrence, Sir Hugh Cairns ultimately saved the lives of many motorcyclists.

Lawrence's last SS100 (Registration GW 2275) was built in 1932 and was on loan to the National Motor Museum at Beaulieu, Hampshire. It is currently on display at the Imperial War Museum in London."

↧

Gary Hocking

↧

Chevrolet CERV II

"The 1950s were a Golden Age for American car companies, but this was not by chance; it was because of designers and brilliant engineers like Zora Arkus-Duntov. Indeed, few innovators can take credit for redirecting the entire focus of an industry. He is rightfully regarded as the “Father of the Corvette,” taking the staid powerplant of its inaugural year and infusing a much-needed injection of youthful aggression: a powerful small-block V-8 that took the Corvette from a delightful cruiser to an all-out sports car. Fuel injection was added to the model in 1957, and a rip-snorting Grand Sport program took hold in the early 1960s. From there on out, the Corvette had cemented its status as “America’s sports car,” as it was capable of going up against the finest competition from Europe, both on the track and from stoplight to stoplight on Woodward Avenue. Here was a man who not only understood the importance of performance, but he also intimately understood its market. The American driver wants fast, he wants loud, and he wants to win.

In order to win, General Motors needed to stay on the cutting edge, and rumors kept circulating that the next Corvette would be mid-engined, in keeping with the developments at Ferrari and Ford, with its GT40. The rumors were largely based on facts, as Chevrolet had been one step away from such a car with its radically different “Chevrolet Engineering Research Vehicle II” (CERV II).

The most extraordinary characteristic about CERV II was Duntov’s attempt at four-wheel drive.

He had been interested in a high-performance, four-wheel drive vehicle since 1935, when he witnessed the startling straight-line acceleration of the “integral drive” Bugatti T53 race car. He also witnessed the Bugatti’s difficulty with maneuvering, as well as the trouble drivers had in managing it. “The problem of force transmission to the ground is almost always present in the design and operation of a racing car,” Duntov wrote in a 1964 memo, “but in the mid-thirties, with 650 horsepower and under 2,000 pounds of running weight...this was a real problem. However, four-wheel drives visualized at that time did not promise to be satisfactory, and one case of execution did not meet with success.” In the late 1950s, with Chevrolet General Manager Bunkie Knudsen and the engineering might of General Motors behind him, Duntov was able to tackle the problem.

The first Duntov Chevrolet CERV was completed in 1960, and it was aimed at open-wheel racing. While it featured advanced construction, it was a relatively conventional design that resembled contemporary IndyCars. Its most notable feature was an all-aluminum pushrod, 377-cubic inch small block that evolved from the 327, which went on to see use in racing Corvette Grand Sports in 1963. It was light and capable of 500 brake horsepower, making it the ideal powerplant to design into the next car.

Duntov began work on the successor in late 1961, intending “to incorporate all the features necessary to make it a successful contender, not only in sprints but in such long distance events as Le Mans and Sebring.” His plan was for a run of six cars, originally designated the G.S. 2/3, “to permit selective usage as two-wheel drive (G.S. 2) [or] four-wheel drive (G.S. 3).” Using the Grand Sport label, as well as frequent references to the Corvette, suggests a familial relationship was on their minds.

Four-wheel drive and the 377 were the starting point for the G.S. 2/3, with members of the same team from CERV I on hand, including engineers and builders Walt Zetye, Ernie Lumus, and Bob Kethmann and stylists Larry Shinoda and Tony Lapine, who were responsible for the stressed fiberglass body. With them, Duntov was able to combine 25 years of thinking about advanced powertrains made with lightweight, Space Age, high strength materials in order to make his car possible. The target weight was a scant 1,400 pounds, and in the initial configuration, it was reportedly near to that, thanks to titanium hubs, connecting rods, valves, and an exhaust manifold.

The four-wheel drive system is equally unconventional. An 11-inch Powerglide torque converter and clutchless two-speed manual gearbox hang from the rear of the car. A driveshaft from where a harmonic balancer would normally be extends to a second 10-inch Powerglide torque converter at the front of the car, with a second semi-automatic transmission. Over the course of hundreds of subsequent skidpad laps through the sixties, Chevrolet tried numerous torque split ratios and gears, with Duntov aiming for 35% of the power delivered to the front end at low speed and 40% at high speed. Much of this technology is related to the automatic transmission that soon appeared in Jim Hall’s Chaparrals via the Chevrolet GSIIa and GSIIb prototypes, with which Hall was more closely involved. Despite the similar names, these were completely different cars that had been built by Chevrolet R&D Chief Frank Winchell.

Ferrari’s 248 SP race car was originally benchmarked as the G.S. 2/3’s target. The Ferrari was ultimately not very successful, but as the Chevrolet came together during 1963 and 1964, it roughly coincided with Ford’s GT40, and had it gone racing, it would have been a direct competitor. Interestingly, the G.S. 2/3 body “did not represent the best open car configuration, but rather the lower part of an aerodynamic coupe,” which the six production cars were to be. Even so, with high-speed gearing and between 500 and 550 horsepower from the 377, Chevrolet saw 212 mph on the track. Geared for a sprint, it was capable of 2.8 seconds to 60 mph.

In the spring of 1964, around the time the car was completed, General Motors informed Knudsen and Duntov that any ideas they had for racing were off the table. Repurposing it as CERV II, Duntov staunchly defended the single prototype, writing, “We feel that in case we are not permitted to go racing, we should obtain permission to demonstrate it...It will show that although GM is not in racing, its engineering is more imaginative and more advanced than anyone else [sic].”

Demonstrations were limited and perhaps not necessary, as racing Corvettes, including the Grand Sport (itself something of a testbed for the 377 engine for CERV II) and Z06, appeared at the same time. CERV II became a test vehicle for future exotic Corvette ideas, and it saw major outings, at least in 1964, 1968, 1969, and 1970. These included tire testing both the original Firestones and new Goodyears, aerodynamic research, and top speed testing at Milford Proving Grounds. The bulk of test time seems to have come from Corvette test driver Bob Clift, who spent hundreds of laps investigating roadholding on a skidpad, where CERV II achieved up to 1.19 Gs in steady state cornering.

Around 1969, Chevrolet began testing CERV II with a new all-aluminum 427-cubic inch ZL1 V-8, which Duntov later said he “retrieved...in the nick of time from the crusher.” He believed this powerplant was capable of 700 horsepower, and he said that he felt that the car was capable of breaking Mark Donohue’s 221.160 mph closed course speed record. In its final (current) configuration, power is conservatively estimated at 550 horsepower, and it weighs 1,848 pounds.

Chevrolet’s last test results are from 1970, after which it was placed into storage. As late as December 1974, when it was sent to the Design Staff Warehouse in Warren, Michigan, it was accompanied by not only a ZL1, but also a spare fuel-injected 377 with dual ignition and a third unspecified SOHC fuel-injected engine, as well as probably another 377. Multiple boxes of spares were also with the car, including 18 unique Halibrand CERV II knockoff wheels. These materials have since disappeared. Shortly thereafter, GM officially retired CERV II and donated it to the Briggs Cunningham Automotive Museum in Costa Mesa, California, where it was displayed for the next 10 years and was periodically shown and even exercised.

When the museum closed in 1986, noted collector and enthusiast Miles Collier acquired the collection, before it was eventually sold to noted philanthropist and car collector John Moores. Mr. Moores eventually chose to donate the car to the Scripps Research Institute, from which it was sold in 2001 to its present caretaker, benefitting SRI’s important medical programs.

Given that the entire drivetrain and running gear was essentially hand fabricated by Chevrolet, and that it is unique to CERV II, the fact that the car is in one piece today is an indication that it must have the same parts it did in 1970. There is no evidence of any significant damage, and its longtime caretaker attests that the blue and white paint appears to have been applied in 1964. A few minor inconsistencies, such as later spark plug wires, probably from the Briggs Cunningham era, have been rectified during the consignor’s 12 years of custody, and it is fully, and almost entirely, in correct period configuration.

The same irreplaceable mechanical components that speak to CERV II’s originality have limited its use in recent years. Nevertheless, it is operational and will still demonstrate performance that will give any modern supercar nightmares.

Chevrolet Engineering Research Vehicle II is among the most important Corvette development vehicles in private hands today. Since leaving General Motors, it has only been owned by four collectors, the Briggs Cunningham Museum, Miles Collier Jr., John Moores, and, of course, the current owner, a well-respected collector in his own right. Its provenance is matched only by its extraordinary performance and earth-shattering horsepower."

↧

↧

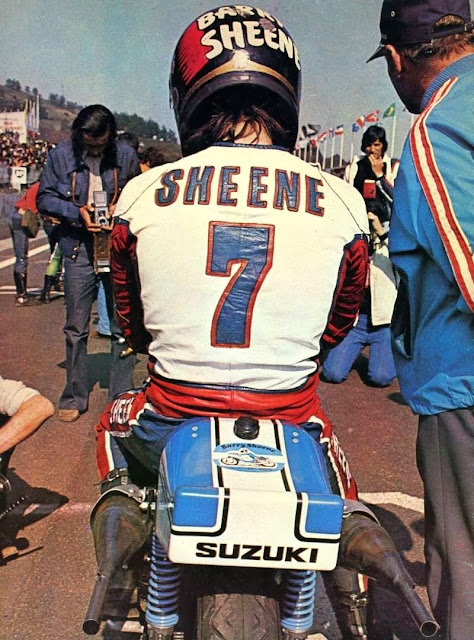

Barry Sheene & Bultaco 125, Zaragoza 1965

↧

Daytona Beach Road Course

"The Daytona Beach Road Course was a race course used for land speed records in the early 20th century, then for stock car races until 1958. The course was used for NASCAR races from 1948 until 1959 when it was replaced by the Daytona International Speedway.

The Daytona Beach Road Course’s first race was sanctioned by the AAA (American Auto Association) on March 8, 1936. Daytona Beach attempted to organize & promote the race that had a $5000 purse, due to winds and bad driving conditions the track became impassable and the race was forced to end early, resulting in numerous disputes about the results. Milt Marion was named the winner by the AAA . Unfortunatley, the city of Daytona Beach lost 22,000 attempting to promote the race and has not promoted an event since.

In 1937 the Daytona Beach Elks Club promoted the racing event and lost money. So in 1938 Bill France, a racer and garage owner in Daytona beach took over promoting the race and was extremely successful. Bill France promoted the race at the Daytona Beach Road Course from 1938 until 1942.

Races were not regularly held from 1942 until 1948 due to WW2.

After the war, The Daytona Beach Road Course was moved to the location north on A1A, the present location of Racing’s North Turn Restaurant & Lounge was the actual mnorth turn of the track. Thousands used to show up to see the races. Organized Events were beginning to be held around the country. Many times, unscrupulous promoters would blow town with the cash and drivers would not be paid. Promoters needed to organize their efforts. Bill France started to hold talks at the Ebony Bar at the Streamline Hotel with other race promoters from around the country they organized themselves and formed NASCAR in 1948.

The racing continued at The Daytona Beach Road Course with events scheduled yearly thru 1958. The Daytona Beach Raod Course closed when the Daytona International Speedway opened in 1958."

↧

Steady Eddie

↧

More Pages to Explore .....